Imagine cruising down the highway, the sun beating down, and your trusty 2008 Ford F250 suddenly turns into a sauna. That’s the nightmare scenario no truck owner wants to face. Thankfully, understanding your AC wiring diagram can be your key to keeping cool and comfortable on even the hottest days. This intricate network of wires and components is responsible for powering your air conditioning system – from the compressor to the vents – and mastering its intricacies can be the difference between sweltering misery and a refreshingly cool cabin.

Image: laskoproductsdiscounttttt.blogspot.com

This guide delves into the world of the 2008 Ford F250 AC wiring diagram, demystifying its complexities and empowering you to troubleshoot those pesky AC problems. From basic components to advanced troubleshooting techniques, we’ll equip you with the knowledge to tackle common issues and keep your truck climatized year-round.

Understanding the Basics: Your Air Conditioner’s Nervous System

Before we dive into the wiring diagram, let’s lay the groundwork by understanding the fundamental components that make up your AC system. These components act as the building blocks, each playing a crucial role in the cooling process:

- Compressor: The heart of your AC system, compressing refrigerant to create the necessary pressure for cooling.

- Condenser: A heat exchanger that releases heat from the pressurized refrigerant into the atmosphere.

- Expansion Valve: Fine-tunes the flow of refrigerant, regulating cooling power.

- Evaporator: Where the refrigerant absorbs heat from the air inside your truck, creating cool air.

- Fan Motor: Circulates air through the system, assisting in heat dissipation and directing cold air into the cabin.

Each of these components is interconnected by a complex network of wires, meticulously laid out in your AC wiring diagram. Now, let’s venture into the diagram itself and decode its secrets.

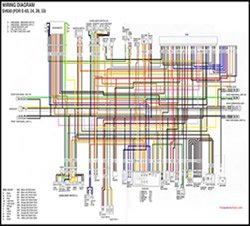

Deciphering the Code: Exploring the 2008 Ford F250 AC Wiring Diagram

Your 2008 Ford F250 AC wiring diagram is a digital map of your truck’s air conditioning system. It’s a valuable tool for diagnosing problems with your AC, whether you’re a seasoned mechanic or a resourceful DIY enthusiast. Here’s what you need to understand:

Key Components on the Wiring Diagram

The diagram will showcase:

- Wires: Each wire is labeled with a color code and a corresponding number, signifying its purpose.

- Relays: These electromagnetic switches control the flow of electricity to various components.

- Sensors: These are strategically placed to monitor AC system performance and send signals to the control module.

- Control Module: The brain of the system, receiving sensor inputs and activating relevant components based on predetermined settings.

- Fuses: Provide protection against electrical overloads within the system.

Image: wiringdiagram.2bitboer.com

Navigating the Wiring Diagram

Understanding the layout is key to navigating the diagram efficiently:

The typical layout of an AC wiring diagram typically employs a standard format:

- Component Legend: A key explaining the symbols and abbreviations used in the diagram.

- Wiring Paths: Arrows indicate the direction of electrical current flow through the system.

- Connectors: These are points where multiple wires join, often labeled with numbers for easy identification.

Finding the right information on your diagram can be likened to searching a detective’s case file. You need to trace the threads of connections to identify the root cause of a problem. This is where a little practice and patience come in handy.

Troubleshooting Tips: Solving AC Issues

With your AC wiring diagram in hand, you can tackle many common AC problems. Here’s a step-by-step approach to troubleshooting:

1. Identify the Symptom

Start by observing what’s going wrong with your AC. Are you getting no cool air at all? Is the air blowing but not cold? Is the compressor not engaging? The symptom is your first clue to narrowing down the cause.

2. Check the Fuse

A blown fuse is a common culprit in AC system malfunctions. Locate the fuse box in your truck, typically near the engine bay or driver’s side, and consult your wiring diagram to find the fuse specifically for the AC system. If the fuse is blown, replace it with a fuse of the same amperage rating. Always double-check the fuse before starting your engine.

3. Inspect the Relays

Relays act as on/off switches, and a faulty relay can prevent the compressor from engaging. Use your wiring diagram to locate the AC relay, often situated near the fuse box. A simple test involves checking for continuity across the relay contacts while energized.

4. Test the Sensors

Sensors monitor vital parameters like refrigerant pressure and temperature. A faulty sensor can confuse the control module, leading to AC system malfunction. Refer to your wiring diagram to identify the location of relevant sensors and use a multimeter to check their resistance readings.

5. Trace the Wires

Your trusty wiring diagram becomes your road map. If you suspect a wire is faulty, use the color codes and circuit paths to trace it from beginning to end. Look for any signs of damage, corrosion, or loose connections.

Professional Guidance When Needed

We’ve covered the fundamentals of understanding your AC wiring diagram and how to perform basic troubleshooting, but remember, some issues may require a more experienced touch. If you find yourself facing a complex problem, it’s always recommended to consult a qualified technician. They possess specialized tools and expertise to diagnose and repair intricate AC system problems.

Keeping Your AC System in Top Shape

Prevention is key. Regular maintenance is essential to ensure your air conditioning system runs smoothly for miles to come. Here are some tips:

- Regular Checks: Visually inspect your AC system for any signs of wear and tear, leaks, or damage.

- Refrigerant Level: Have the refrigerant level checked by a professional to ensure optimal performance.

- Air Filter Replacement: Change the cabin air filter regularly to improve airflow and prevent dust from clogging the evaporator.

2008 Ford F250 Ac Wiring Diagram

Conclusion

Mastering the language of your 2008 Ford F250 AC wiring diagram empowers you to tackle common AC problems head-on. By understanding the layout, recognizing key components, and implementing effective troubleshooting methods, you can restore your truck’s cooling capabilities and keep your cabin comfortably cool, even on the hottest days. Remember, while the diagram is your guide, seeking professional help in complex situations is crucial. Remember to regularly maintain your AC system to prevent future issues. Embrace the knowledge, and drive happy and cool!